By Yokogawa RAP | 19 August 2021

There are many reasons why safe Control of Work (CoW) really matters, particularly in industries that may not be as obviously dangerous as high hazard chemicals, oil & gas and minerals handling. These are of course where control of work started, because of the significance of several disasters, starting with Sevesso (Italy) in 1976, when a bursting disc on a chemical reactor ruptured, resulting in a release of gas over a 20 min period that affected 17,000 people in the town near the plant that gave the disaster its name.

Fortunately, there was no immediate loss of life from Sevesso, but it made regulatory bodies take note and subsequent incidents, such as the loss of life on Piper Alpha in 1988, where 167 workers died, have only increased the focus on safe working practices.

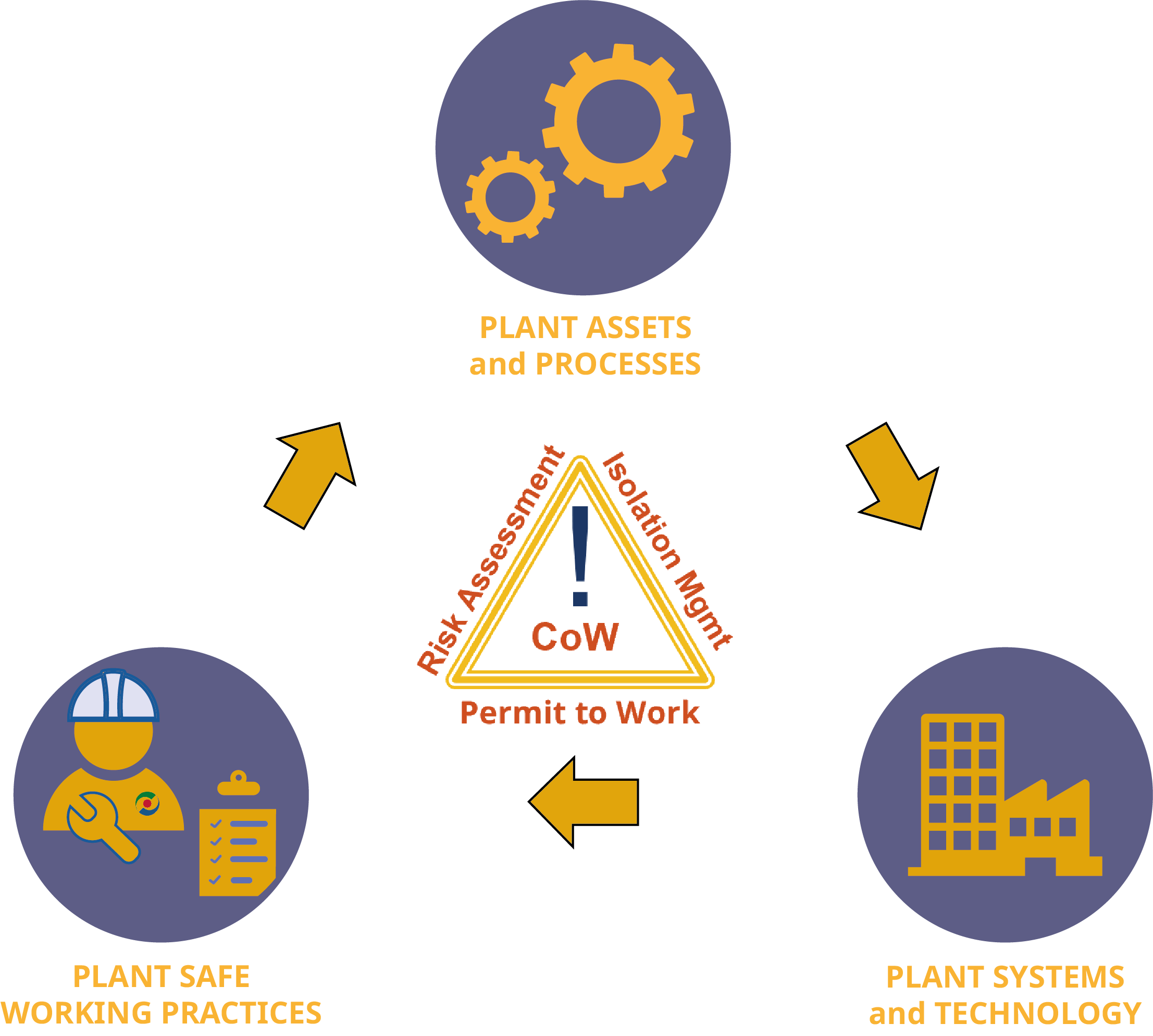

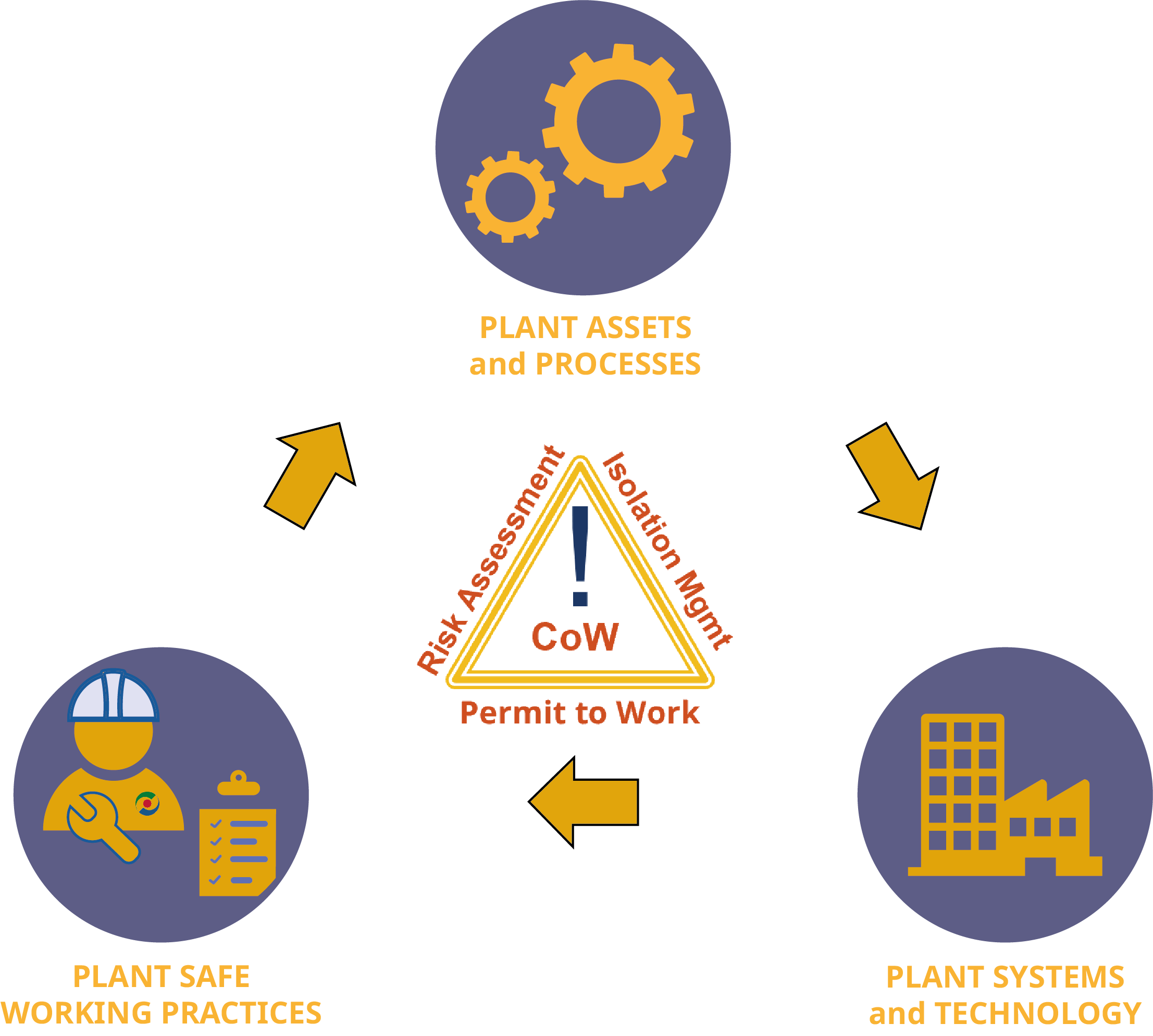

A chemical reactor or and oil rig are of course obvious risks, but what is control of work and why does it matter? Well, 4 reasons stand out, but firstly, let’s look at what control of work really is.

“In 2020, just in the UK, 1.6 million people were classed as suffering from work related illnesses and in 2019/20 38.8 million days were lost to work related ill health and non-fatal work injuries” Source: UK HSE data

There is often a fourth criteria that is applied to Control of Work, which is the communication of the information to the people doing the work, which can be particularly important as the workforce changes, such as during a shift change or the like.

“We searched for an application that would be appropriate for the level of risk present on site and that would be easy to use and well accepted by the plant workforce. A system that would deliver additional benefits to standard (paper based) permits and was capable of being used at other parent facilities for ‘best practice’ sharing was targeted. The application we choose after researching all options was RAP” Project Safety Lead (Large Chemical Facility)

So let’s look at the 4 main reasons CoW matters and why digital systems make sense:

An obvious one, but amazingly the most common reason for incidents across all industries is human error, mostly caused by a lack of an adequate assessment of risk. The logical reason being that if we knew what the risks were and did something about them then we wouldn’t have had an incident!

It’s interesting that over time the breakdown of why accidents happen hasn’t really changed. The three main reasons for fatalities are almost always:

These broadly make up around 30% each of any study and in reality, these aren’t really high hazard industry related. In fact, it’s often the case that humanity spots the big incident potential but ignores what on the face of it, should be an obvious risk that then leads to an incident. An good example of this is welding. We all know to keep away from the sparks and to wear specific safety equipment to not be blinded and to keep the gas bottles out of direct sources of heat and sunlight, but depending on where the weld is being done, a generator is often required and it ends up being that which causes the incident through fumes, overheating, running dry, etc.

The RAP4 system is designed to help with this by placing risk assessment firmly at the heart of the process of setting out the work so that additional factors are easier to spot and control.

Surely all this safety stuff takes time. Why can’t we just get on with the work? I’m often confronted with views on social media of people having new roofs put on their houses and there is the house with a big flag raised proudly in the middle of the front lawn and behind it, workers are scurrying about the roof……. With no fall protection and quite often, with no view at all as to safety.

Here I will paraphrase OSHA in that “Everyone has the right to go to work and expect to come home at the end of the day in one piece”. Yes, it can save time to not put on a harness and not consider what might happen if someone falls off a roof, but what is the cost of a life lost or ruined by the fall? Construction is one of the highest incident workplaces and standards vary wildly depending on the companies doing the work.

What’s that got to do with efficiency? A consistent working methodology and a culture that embraces it, leads to everyone knowing what is required and being happy to do it because it is for their own safety. This cultural acceptance leads to markedly less incidents and leads to greater operating efficiencies than were achieved without putting these rules in place. It’s that cultural element that leads to safety. It’s why we teach our kids to look both ways before crossing as opposed to saying just run across the road because it’s faster.

Digital systems like Yokogawa’s RAP4 software are designed to make the workflow process of risk assessment, setting out the work and ensuring that it can be done safely as smooth as possible, using best practice workflows to make the system easy and intuitive to follow, meaning that everyone can be involved in safe, efficient working.

Compliant working means working in compliance with standards and rules that may be set at business, site, national or international level. And of course, the big problem with standards is that they keep changing! These changes mean that the paper forms that were printed two weeks ago are suddenly obsolete and have to be re-written in the constantly moving minefield that is compliance.

This is one area where digital systems such as RAP4 have a huge advantage in that they are much easier to keep up to date to ensure that businesses are always in line with the latest guidance. Examples include declaration changes for certain types of work or ensuring that certain signatures are always required before carrying out activities. Again, these don’t need to be high hazard industry signatures. As an example, the building manager should always sign before anyone goes to do work on the roof so that they know someone is up there and if they don’t come down after a set period then the issue can be immediately investigated.

It's often the case that compliance is seen as a bad thing, but the whole purpose of bodies such as OSHA, HSE, ISO, ASME and the like are to set in place standards that ensure that appropriate guidelines are in place to ensure safe working of people and equipment.

The strong administration capability of the RAP4 system allows the user to be in control of the legislation they require to maintain compliance and to be able to easily adjust things as rules change. This capability means that unnecessary bespoke programming isn’t required and systems can be kept up to date quickly and importantly, locally.

By smarter working, I don’t mean that computerized systems are smarter than paper. Often they aren’t and the software is nothing more than digitized forms, that while making things more efficient, don’t really change the way we work, other than to perhaps get us to an incident more quickly and efficiently!

What smarter working really means, is having the capability to easily acquire new learning and to apply it for the benefit of future working practices. A simple example could be making sure that a vehicle is always lined up with e.g. a trailer. Plant A could work out that wheel guides always ensure that the vehicle is straight and a traffic light visible to the driver always makes sure the distance is right. However, plants B through F may not have thought of this or may have come up with their own independent solutions. How many times have we all come up with a solution and thought “that worked, I must remember to do that next time”?.......... and then we forget and are half way through doing the job 6 months later only to remember that we’d found a better way to do it previously.

Being able to capture observations and / or suggestions for improvement throughout the work process and through any auditing processes that may run alongside them can bring huge benefits. Digital systems can collate these learnings and make them much more visible so that they can be easily incorporated to be automatically applied for the future. These learnings can be further enhanced by allowing them to be shared across multiple sites if required, leading to smarter, safer working for everyone as best practices can propagate easily.

To conclude; a thought. Industry 5.0 is defined by the European commission as

“the next step (Industry 5.0) is to place the wellbeing of the worker at the centre of the production process and to use new technologies to provide prosperity beyond jobs and growth, while respecting the production limits of the planet” Source: European Commission

Allied to this there is an increasing drive within standards such as ISO 9001, ISO 45001 and the like to drive risk and its management to be a core responsibility of any organization and not something that can be delegated to be the sole domain of safety professionals. This is simply because safety is too important to not be everyone’s concern.

Considering this, surely it makes sense to use systems that are designed to help businesses to maintain and improve safety standards on an ongoing basis and to ensure that working practices are adequately controlled to reduce the risk to both the workforce and the business itself to being as low as reasonably practicable. Historically, this may have been difficult, heavy on paperwork and time consuming for little real gain, and it’s why there has been a reluctance in many industries to embrace the benefits of Control of Work.

With over 30 years’ experience in the field, helping clients all over the globe to continually improve their safety culture, why not talk to Yokogawa about RAP4 digital Control of Work software and how we can help make your workplace an efficient, compliant, safer and smarter place to be.